Structure and features of Bio-Clean diaphragm valves

Valves with sanitary specifications suitable for manufacturing facilities of such as pharmaceuticals, bioprocesses, cosmetics, food, and semiconductors.

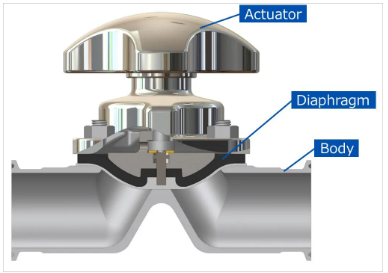

Basic structure of valve

|  |

| Basic structure of valve |

Features of Bio-Clean diaphragm valves

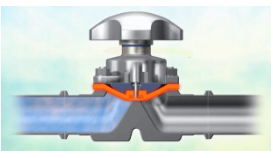

①High airtightness and contamination prevention structure

・Since the flow path is completely isolated from the actuator and the outside by the diaphragm, it has excellent airtightness and no contamination of the fluid.

・Our diaphragms are subjected to various tests under severe conditions to confirm their durability and safety, high sealing reliability against external leakage and valve seat leakage.

②Flow path structure with excellent cleanability

・There is no dead space (pocket or liquid pool) in the flow path and no space for germs to enter. It has excellent cleanability and is advantageous for CIP (Clean-in-place) and SIP (Sterilization-in-place) in terms of its effectiveness and cleaning duration.

・The surface of the main body is buffed or electropolished, and there is little adhesion to the flow path wall surface, and even if it adheres, it can be easily removed by cleaning.

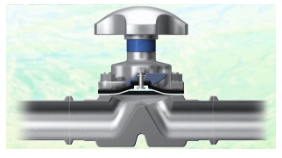

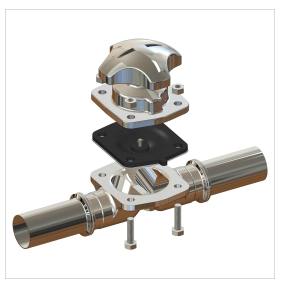

③Good maintainability

・This is a simple structure of three parts:the Actuator, the diaphragm, and the body. The top entry structure makes it easy to perform maintenance work such as diaphragm replacement of the valve at piping.

・As a characteristic of the diaphragm valve, the initial performance is recovered by replacing the diaphragm with a new one.

・Each unit is interchangeable, so it is easy to change the actuator by the application. In addition to standard manual operation and pneumatic operation, flow control and electric operation are also available.

④≪ High-quality, High-performance ≫ sanitary diaphragm

・Our NEW PTFE diaphragms are fluorocarbon resin diaphragms with excellent cleanliness, creep-resistance, penetration-resistance, and abrasion-resistance developed with our own techniques.

・Based on our extensive experience and reliable technological capabilities for more than half a century, we conduct various tests under severe conditions to confirm durability and safety.

・Complies with various standards such as the Food Sanitation Act (Japan) and FDA, USP Class-VI.

⑤Wide products lineup complied with various standards

・Complied with various standards such as JIS, ISO, ASME-BPE.

・A wide range of products are available, including dead space countermeasure products, lining valves, and combination valves. It is also possible to manufacture the main bodies on the user's request.